Background

The oven is commonly used equipment in the printed circuit board (PCB) process. Whether it is after printing ink, after welding, or after applying protective paint, the semi-finished products need to be sent into the oven to be dried at an appropriate time and temperature. The traditional PCB baking process is manually controlled by personnel. If the an improper operation or input error, it is possible to destroy the entire batch of semi-finished products. Moreover, the traditional equipment is not connected to the computer, and there is no complete baking record to trace back to find the problem.

Challenge

1. Manual operation, high error rate;

2. It is difficult to collect information and the source of the problem cannot be traced.

Introduction

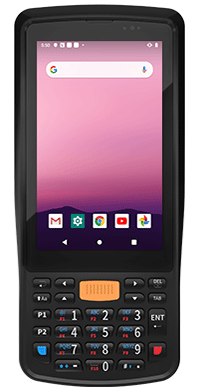

Emdoor Info Industrial Control Computer has built a strong foundation for the PCB oven monitoring system to help solve the combination of oven automation and the Internet of Things. The oven operator only needs to enter the system in advance for different baking temperature curves required by different batches of products and processes. Simply scan the barcode on the same batch of semi-finished products with a handheld barcode scanner on the spot, and it will bring out the corresponding material number information, work order, and temperature curve. The system will also leave a record of the baking history of all products for future inquiries.

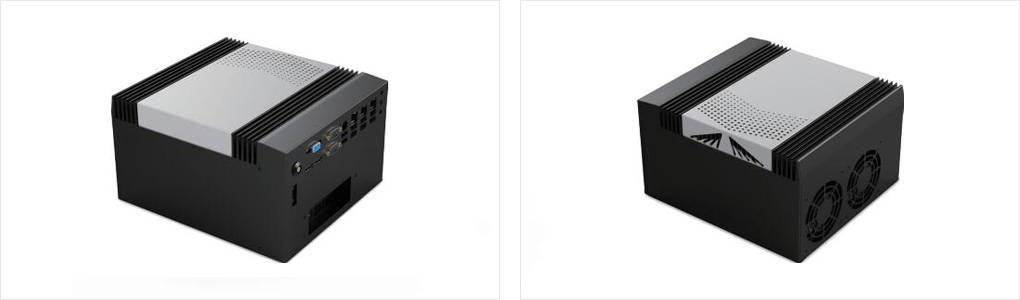

In response to this PCB oven monitoring system project, Emdoor Info provided the EM-MP300HP embedded fanless industrial control machine which was built at the oven operation site. Because of its rich serial interface, the industrial panel PC can support PCIE16 discrete graphics and excellent scalability to connect field devices. The functions of the rugged industrial PC include connecting to the oven temperature control to start automatic baking, connecting the operator scanner to read batch material numbers and work orders, and connecting different custom programs to pick modules. By collecting switches, flow information and other sensor data, a complete baking record is established.

In addition, each oven automatic baking process is executed and recorded by an industrial computer, and related information is connected to the background server in series. The integration with the Factory Manufacturing Execution System (MES) has become one of the important steps for the PCB factory to move towards the Industry 4.0 Intelligent Chemical Factory.

Reducing input errors and increasing productivity and yield.

Establish a complete baking record in a digital way for customers to quickly grasp the oven use information and trace the process afterwards.

Cross-platform integration of other factory management application systems, and make the front office operations and background management functions fully integrated.

Thank you for your attention on Emdoor Rugged PC!

Please fill the form to let us know your need. We will get in touch with you ASAP.