At the heart of modern manufacturing operations lies a crucial technological backbone: the Industrial Panel PC. This specialized computing device is purpose-built to meet the unique demands of industrial environments, serving as a central hub for control, monitoring, and data management in various manufacturing settings.

The primary use of Industrial Panel PCs is rooted in their role as controllers in manufacturing systems. These robust devices are designed to interface seamlessly with machinery, sensors, and other industrial components. Their rugged build, often featuring hardened enclosures and resistant screens, ensures durability in harsh manufacturing conditions. Industrial Panel PCs become the nerve center of automated processes, providing real-time control and facilitating efficient coordination of production lines.

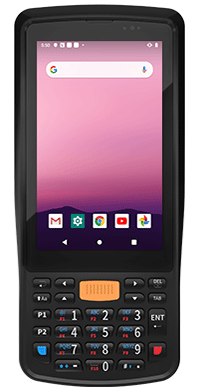

One of the key functionalities of Industrial Panel PCs is their role in Human-Machine Interface (HMI). These devices offer an intuitive and user-friendly interface that allows operators and technicians to monitor and control industrial processes. The touchscreen capabilities of Industrial Panel PCs simplify the interaction between humans and machines, enabling swift adjustments, data input, and troubleshooting. In essence, Industrial Panel PCs bridge the gap between operators and the complex machinery they oversee.

In manufacturing, precision and quality assurance are paramount. Industrial Panel PCs play a pivotal role in ensuring the highest standards are maintained throughout the production process. By integrating with sensors and measurement devices, these devices monitor critical parameters, analyze data in real-time, and contribute to the identification and prevention of defects. The use of Industrial Panel PCs in quality assurance elevates manufacturing standards and minimizes the risk of subpar products reaching the market.

Data management is a cornerstone of modern manufacturing, and Industrial Panel PCs excel in this domain. These devices serve as data hubs, collecting and processing information from various sensors, machinery, and production stages. The robust computing power of Industrial Panel PCs enables them to handle large volumes of data, facilitating real-time analytics and decision-making. This capability is instrumental in optimizing processes, predicting maintenance needs, and ensuring overall operational efficiency.

The versatility of Industrial Panel PCs is evident in their adaptability to varied applications within the industrial landscape. Whether deployed in automotive manufacturing, food and beverage processing, or pharmaceutical production, Industrial Panel PCs can be customized to meet the specific requirements of each industry. Their flexibility extends to the ability to integrate with specialized software and hardware, making them indispensable tools in diverse manufacturing environments.

The networking capabilities of Industrial Panel PCs contribute significantly to the overall connectivity of the production floor. These devices are often equipped with multiple communication ports, allowing them to connect with PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition) systems, and other industrial automation components. The result is a cohesive network where Industrial Panel PCs serve as communication hubs, ensuring seamless coordination between different elements of the manufacturing process.

In the era of Industry 4.0, where the integration of digital technologies is transforming manufacturing, Industrial Panel PCs are at the forefront of advancements. These devices play a crucial role in implementing smart manufacturing practices by facilitating connectivity, automation, and data exchange. As the manufacturing landscape continues to evolve, Industrial Panel PCs will remain integral to the realization of Industry 4.0 goals, ensuring that factories operate with unprecedented efficiency, flexibility, and responsiveness.

Looking ahead, the use of Industrial Panel PCs is poised for continuous evolution. As manufacturing processes become more sophisticated and interconnected, Industrial Panel PCs will likely see enhancements in processing power, connectivity options, and integration with emerging technologies such as artificial intelligence and edge computing. The trajectory is clear: Industrial Panel PCs will continue to be indispensable tools, driving innovation and efficiency in the ever-evolving landscape of industrial automation.

You may also be interested in these products:

Thank you for your attention on Emdoor Rugged PC!

Please fill the form to let us know your need. We will get in touch with you ASAP.