Challenge

The client is a company focused on industrial robot manufacturing and mechanical parts processing, before using Emdoor Information products, the client has been operating industrial welding through dual-station alternation of artificial and robot, which has been missing a monitoring mobile terminal to connect them, resulting in low welding efficiency, low precision, and even a threat to physical safety. Therefore, there is an urgent need for the client to adopt an intelligent terminal that can perform industrial welding tasks in a steel-splashing environment.

Benefits of Rough Industrial Tablets For Manufacturing Automation - EM-Q86

EM-Q86 rugged tablet PC shows excellent performances in waterproof and dust-proof, shock-resistant, and stable, which can withstand the drop and continuous vibration in the welding site, so that the operators can focus on the completion of the welding tasks. With an easy-to-use operating system and a clear display screen, it is convenient for operators to efficiently monitor welding results in real time, find and track problems, greatly improve welding efficiency, and reduce loss costs and labor costs as well.

Challenge

The welding site is often accompanied by unstable conditions such as steel splashing, dust flying, and signal obstruction, so the equipment and operating terminals are needed to be more stringent than ordinary equipment for ruggedness, stability, and safety. Due to the professionalism of welding work, there are also high requirements for the technical ability of operators, but the resources of technical personnel available for deployment are limited, which increases the difficulty of employing enterprises to a certain extent.

The client is a company focused on industrial robot manufacturing, mainly serving industrial buildings and the welding processing of mechanical parts. Before using Emdoor Information products, the client has been using manual and robot dual-station alternation to complete the welding work. When the robot is welding, the welding gun is maintaining the welding state, when in manual welding, the robot will stop working and wait for the assembly of the workpieces, thus wasting time. Besides, skilled professional welders are limited due to a welder matches a robot for alternation work, and the precision of manual welding is also biased, leading to a waste of human resources and low welding efficiency. In addition, smoke will be produced during the welding process, which will cause physical harm to the operators, pollute the robot nozzle and other equipment parts, and greatly affect the conduction of welding operations and the quality of welding parts.

The above problems have caused a lot of inconvenience and troubles to the client, therefore, the client urgently needs to apply a professional, rugged, and intelligent operating terminal to achieve automatic welding manufacturing, but the current consumer mobile equipment can not meet the needs. At this time, a ruggedized tablet PC has become the first choice for the client.

Solution

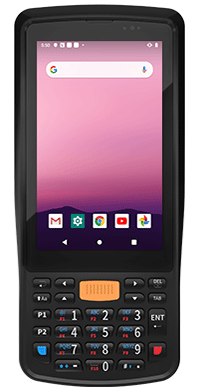

After rigorous comparative analysis and user testing of several reinforced mobile devices on the market, the client finally selected the EM-Q86 rugged tablet PC of Emdoor Information as the operating terminal equipment for its automatic welding manufacturing according to its own needs and usage scenarios, to replace the previous manual welding method.

Solution of Rough Industrial Tablets For Manufacturing Automation - EM-Q86

Designed for use in harsh environments, the EM-Q86 rugged tablet PC combines reliable robustness with powerful computing performance. Its rigorously sealed body is designed to withstand fine particles from welding sites, the shock of crashes, and maintain normal and stable operation in extreme temperatures ranging from -20°C to 55°C. EM-Q86 rugged tablet PC is equipped with an ARM architecture octa-core processor and an Android 10 operating system, which is compatible with client-developed application systems and robot programs, executing multiple tasks simultaneously and processing data information quickly. The front and rear dual cameras support high-definition imaging and display, and output integrated information while detecting small welds, solving the problems of thin plate joints, and tracking welding position. If the workpieces are found to have shape and position deviation before welding, the robot welding trajectory can be corrected in advance. During the welding operation, the operators use the EM-Q86 rugged tablet PC to operate the robots to complete the welding details and monitor the welding effect of the robot in real time. Additionally ,the EM-Q86’s high-definition and bright 8-inch screen outputs intuitive and reliable information to help the operators find problems and adjust in time. With EM-Q86's stable dual-band WiFi, 4G, Bluetooth, and other network communication connections, welding data can be uploaded to the system background anytime and anywhere for follow-up tracking and regular cleaning and maintenance of welding equipment, to maximize the quality and efficiency of welding operations.

The Android 10 operating system on the EM-Q86 rugged tablet PC is perfect for client-developed systems and robotics. After the EM-Q86 is equipped for the station of the client, the welding work that originally needed to be completed by alteration of manual and robot, now an operator can use the EM-Q86 to monitor and operate three robots to complete welding at the same time, so that human resources can be fully utilized and deployed, reducing labor costs and maintenance costs.

The original production speed of manual welding is 40-60cm/min, and 70 Angle flanges can be welded every day. After using EM-Q86 rugged tablet PC with robot, its easy-to-use operating system reduces the difficulty of operations, so that even ordinary operators can be skilled in operation. Now the client can weld 420 Angle flanges every day, which increases welding efficiency by 6 times.

Through the EM-Q86 rugged tablet PC and the client's operating system, operators can monitor and view the robot welding trajectory, welding progress, and workpiece quality in real time, and view highly integrated information at any time in EM-Q86's 8-inch high-definition and high-brightness screen that is not affected by strong sunlight, so that operators can keep track of the work situation and problems at any time to achieve visual management.

The EM-Q86 industrial tablet is protected by IP67 industrial-grade and has passed the MIL-STD-810G test standard to operate normally and efficiently in extreme temperatures from -20°C to 55°C, and can maintain normal operation even when accidentally dropped at a height of 1.22 meters, which is enough to withstand heat, dust, and knock falls in the welding site. While ensuring safe operations, it also protects stored data from damage and loss, so that operators can focus on the completion of welding work without worrying about equipment failure.

The built-in 8500mAh/3.7V polymer lithium-ion battery of the EM-Q86 rugged tablet PC lasts 12 hours of continuous operation on a full charge the Type-C interface supports fast charging, and accessories such as the docking charger is optional for convenient charging, which can support all-day work in difficult charging environments.

You may also be interested in other industrial tablets provided by Emdoor, one of leading rugged tablet manufacturers in China:

Thank you for your attention on Emdoor Rugged PC!

Please fill the form to let us know your need. We will get in touch with you ASAP.