Background:

The traditional maintenance plan of a ship's rotating equipment requires the ship to pause its operation once every 5 years or in some cases more frequently for a month or even more and conduct comprehensive equipment dismantling inspection. Long maintenance periods reduce the operational efficiency of the vessel. Therefore, condition monitoring with a non-destructive technology such as vibration analysis, which can simplify ship inspection and shorten the maintenance window, has become the best solution to help shipowners and ship management companies to maintain industry competitiveness.

Challenge:

The marine environment is humid and in several geographical locations very warm, and the air is highly corrosive due to salt. Computer equipment for non-destructive testing such as vibration analysis should withstand salt spray corrosion, water mist, and the huge temperature difference between indoors and outdoors to perform daily tasks flawlessly. Furthermore, it also has to cope with the physical shock caused by a ship moving, which cannot be achieved by ordinary computers.

Solution:

The Emdoor EM-I10J 10-inch rugged tablet windows 10 provides the most cost-effective option for efficient ship inspection, as it has a fully rugged shell, and is salt spray tested, certified to U.S. Military-810G and IP65-rated for water and dust resistance. It’s easy to use in offshore environments where corrosive electronics exist. Another key factor in choosing the I10J tablet is that it has a high-performance Intel quad-core processor that is perfectly compatible with the HAT Analytics 2nd generation digital health monitoring system Ad|Vi|Se, guaranteeing stable diagnostics.

Benefits:

Compared with the traditional maintenance methods, the intelligent ship condition monitoring solution brought by the cooperation of the I10J tablet and the HAT Analytics digital health monitoring system Ad|Vi|Se provides a faster, more effective and reliable predictive ship machinery maintenance mode. Through portable data collection, instant health condition analysis and diagnostics, unplanned downtime and malfunctioning equipment issues are forewarned and repaired, preventing costly and time-consuming catastrophic failure events.

Challenge:

The normal operation of a ship depends on the availability of machinery on board, and regular maintenance is necessary to ensure that the ship is always in good condition. Traditional ship maintenance of the rotating equipment is based on regular openings onboard or in a shipyard, which requires dismantling transportation, and professional inspection. Thus, ships need to go out of business until the maintenance is completed. The workload is large and time-consuming, which increases the pressure on the shipping company. However, predictive maintenance programs can transform maintenance from reactive to proactive, preventing potential failures with early problem detection, increasing equipment lifespan and shortening maintenance windows.

HAT Analytics, a leading provider of predictive maintenance services, delivers innovative digital condition monitoring solutions that require the assistance of rugged mobile computing devices. Because operating offshore, where extreme temperatures, shock, vibration, and salty air are common, overly fragile equipment can add to the high cost of hardware replacement. What mobile computer is their best choice? To find this answer, HAT Analytics conducted an extensive search for data acquisition tablets that meet communication standards and field durability standards.

Solution:

Emdoor's EM-I10J industrial tablet is an ideal choice for HAT Analytics 2nd generation of digital health monitoring system Ad|Vi|Se. As part of the overall solution, its robustness and powerful computing power allow the digital health monitoring system to stably perform real-time monitoring and diagnosis of the ship's mechanical status.

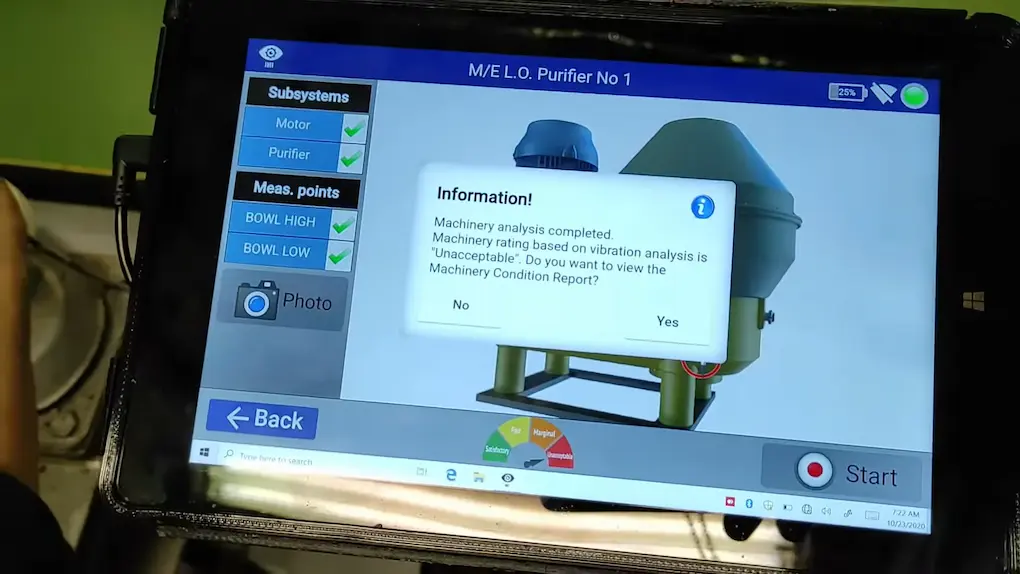

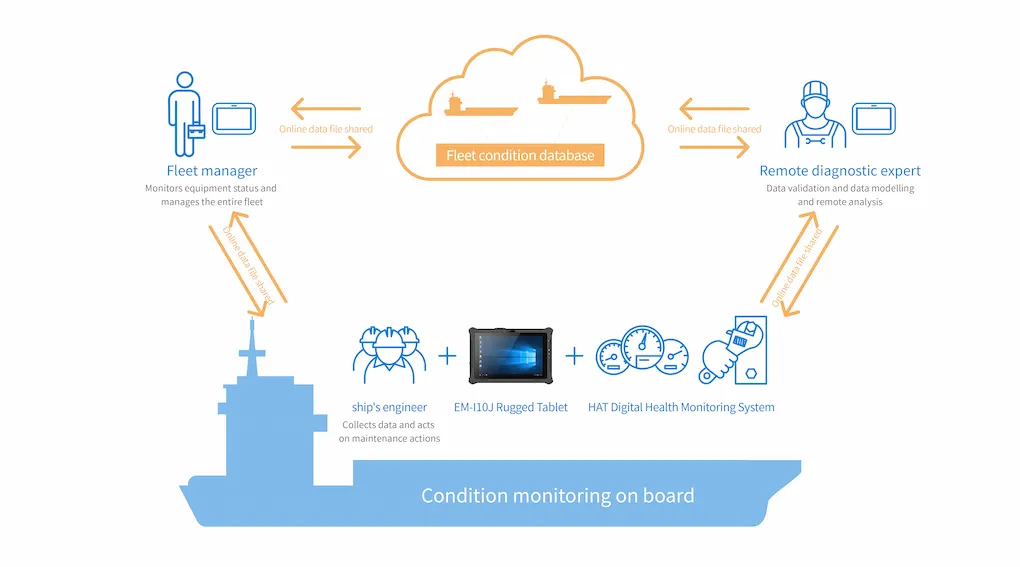

The EM-I10J industrial tablet windows, which operate in cooperation with the HAT Analytics digital health monitoring system Ad|Vi|Se, convert the collected vibration data into an easy-to-understand health report which is presented to the crew via a highly interactive user interface. With the intuitive data display, crews can get measurement results and locate the root cause of the fault faster, and maintenance can be carried out more quickly. Meanwhile, the inspection report will also be automatically generated and transmitted to the cloud server for validation and machine learning modelling through the low-latency network of the EM-I10J tablet. This increases the reliability of the health monitoring system and through the AdViSe CM Dashboard the ship's superintendent and fleet manager can securely access the information and several condition monitoring metrics of the fleet from anywhere. In the face of difficult mechanical problems, the staff can take pictures of abnormal equipment through the EM-I10J high-definition rear camera, and feed them back to the cloud to seek help from remote analysis and diagnosis by the HAT team of experienced engineers.

The EM-I10J rugged tablet meets all HAT Analytics expectations for the Ad|Vi|Se device performance and durability, giving technicians the stable platform they need to inspect, debug and troubleshoot in a variety of situations, allowing them to further their work maintenance tasks.

The marine environment involving salt exposure is a huge challenge for computing equipment. Emdoor EM-I10J rugged tablet windows provides unique anti-corrosion technology, its sealed port design can prevent salt spray damage to the system during the long-term strict salt spray test process, reducing additional costs caused by computer failures and work interruptions.

The EM-I10J is capable of working in a wide range of temperatures from -20 to 60 degrees Celsius, which is also critical for offshore technicians. Because they often need to work in extreme heat at sea, direct sunlight, and other harsh weather conditions, the I10J as an auxiliary tool needs to face the harsh working conditions with them to provide reliable on-site service.

The advantages that the EM-I10J rugged windows tablet offered to the HAT Analytics 2nd generation systems is not only in its durability but also in its stable network connection. The high-quality network transmission of the EM-I10J speeds up the time it takes for field technicians to access diagnostic data and make remote diagnostic decisions, allowing them to work with a higher level of field efficiency.

Thank you for your attention on Emdoor Rugged PC!

Please fill the form to let us know your need. We will get in touch with you ASAP.