Inventory of Warehouse Industry

As a leading manufacturer and supplier of rugged handheld terminals and tablet PCs, Emdoor INFO empowers enterprises to transition from manual operations to digital, transparent, and efficient systems. Our advanced barcode recognition technology streamlines cargo information collection and inquiry, revolutionizing warehouse operations. This article is part of a seven-part series on warehouse and logistics management, with this installment focusing on outbound management. We’ll explore the challenges of traditional methods, showcase the transformative capabilities of Emdoor INFO’s EM-T50 rugged handheld terminal, and highlight why our manufacturing expertise makes us the trusted partner for warehouse automation solutions.

In today’s hyper-competitive market, enterprises are under immense pressure to enhance production efficiency and minimize operational costs. Warehousing and logistics management have become critical pillars across industries, driving supply chain success. However, outdated systems with low levels of informatization and automation often lead to chaotic inventory management, fragmented express package data, and persistent inefficiencies. To stay competitive, businesses must design and implement robust warehouse management processes that boost turnover rates, reduce capital tied up in inventory, and eliminate unnecessary storage costs.

The challenge of the inventory

Traditional, manual-based outbound processes for picking, packing, and shipping are inefficient and create numerous challenges:

1.Time-Consuming and Labor-Intensive Manually locating, verifying, and preparing goods is slow, especially with high order volumes, leading directly to shipment delays and increased labor costs.

2.High Error Rates Manual operations are prone to errors like picking the wrong item, miscounting, or mislabeling. This results in incorrect shipments, customer returns, and damage to the company's reputation.

3.Inefficient Data Management Manually transcribing paper records into a system is tedious and error-prone. The resulting data lag leads to inaccurate inventory information, impacting future management.

4.Lack of Real-Time Visibility Managers have no live view of inventory levels or order statuses, making it difficult to respond to stock shortages or demand shifts and causing delayed decisions.

5.Inventory and Accounting Discrepancies Manual updates often cause mismatches between physical stock and system records, leading to financial issues, complicating audits, and disrupting replenishment cycles.

These challenges underscore the necessity of adopting modern technological solutions to optimize outbound management.

The Solution of the inventory

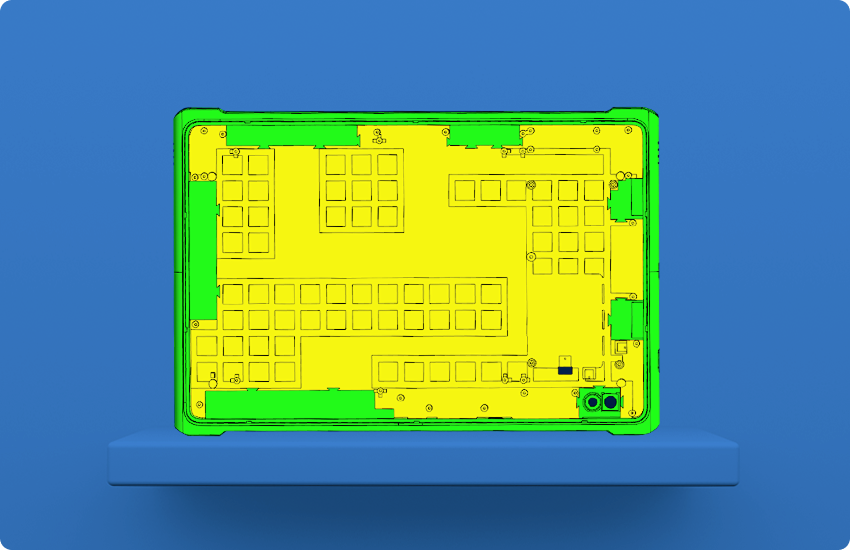

As a trusted manufacturer and supplier, Emdoor INFO designs cutting-edge solutions to address the inefficiencies of traditional warehouse operations. Our EM-T50 rugged handheld terminal is purpose-built to transform outbound management, offering a seamless blend of durability, automation, and intelligence. Here’s how it works:

Revolutionizing Outbound Operations:

Real-Time Data Access: The EM-T50 connects to wireless networks, enabling operators to receive outbound orders instantly, eliminating delays associated with manual order retrieval.

Advanced Barcode Recognition: Equipped with an imported scanning head, the device automatically identifies and verifies products, reducing reliance on human judgment and minimizing errors.

Instant Data Synchronization: Scanned data is uploaded to the central database in real-time, ensuring inventory records remain accurate and up-to-date without manual intervention.

Intelligent Verification: The terminal’s system flags discrepancies—such as incorrect items or quantities—before they become costly mistakes, ensuring precision in every step.

Backed by Emdoor INFO’s rigorous manufacturing standards, the EM-T50 is engineered for reliability in demanding warehouse environments, delivering consistent performance that businesses can depend on.

Application effectiveness

1. The EM-Q51 handheld terminal can replace manual labor to count a large number of goods in a short time, and the system automatically counts the quantity of goods, which greatly reduces the workload of workers.

2. With an RFID UHF handle, it can quickly read a large number of barcode information in batches for inventory, and improve inventory efficiency.

3. The EM-Q51 handheld terminal has a stable mobile network to ensure that data can be shared in real time, and managers can understand inventory information in time to make decisions about the next step.

4. Directly upload the inventory data to the ERP system through the handheld terminal EM-Q51, avoiding manual secondary data entry errors.

Based on our deep understanding of these industry| problems, we have created a set of targeted solutions based| on the concepts of innovation, efficiency and reliability.

Based on our deep understanding of these industry| problems, we have created a set of targeted solutions based| on the concepts of innovation, efficiency and reliability.

Frequently Asked Questions

Why Choose Emdoor INFO as Your Supplier?+

As a leading manufacturer and supplier of rugged handheld terminals, Emdoor INFO stands out for its commitment to quality, innovation, and customer success.

1. Unmatched Durability+

Our devices, including the EM-T50, are engineered to withstand harsh warehouse conditions, ensuring long-term reliability and minimal downtime.

2. Cutting-Edge Technology+

Emdoor INFO invests in advanced barcode recognition and wireless connectivity, delivering solutions that keep pace with industry demands.

3. Customizable Solutions+

As a manufacturer, we offer tailored configurations to meet specific warehouse needs, ensuring seamless integration with existing systems.

4. Global Support+

Our dedicated support team provides ongoing assistance, from implementation to maintenance, ensuring customers maximize the value of our products.

5. Proven Expertise+

With years of experience in rugged device manufacturing, Emdoor INFO delivers solutions trusted by warehouses worldwide.

To learn more about the EM-T50, visit Emdoor INFO’s product page or explore warehouse automation trends on Forbes’ logistics insights.